TRAINING

Asian and Pacific developing countries generally lack trained personnel to produce, prescribe, repair and maintain assistive devices. These trained personnel include:

- (a) Orthotic/prosthetic engineers;

- (b) Orthotic/prosthetic technicians;

- (c) Speech pathologists;

- (d) Audiologists;

- (e) Ear mould technicians;

- (f) Optometrists.

The ratio of trained rehabilitation personnel to people with disabilities should ideally be as large as possible. The actual size of this ratio will depend on, inter alia, a country's priorities and financial resources. It is likely, however, that it will be difficult in any developing country to train sufficient numbers of rehabilitation specialists to provide needed services.

Instead, it may be easier to provide services in rural areas by training people who are already living in rural communities, especially those who are working there in related fields. Multipurpose technicians, local artisans, and personnel working in various other aspects of rural development can be trained in the repair and maintenance of assistive devices.

For example, many people with disabilities can get mechanical devices, such as wheelchairs and tricycles, repaired by bicycle mechanics, welders and local artisans. These local mechanics and artisans, however, may not have the parts necessary to repair a wheelchair's castor wheel, wheel axle or castor wheel axle. Furthermore, thermoplastics are increasingly used in orthoses, prostheses and wheelchairs, whereas the local mechanics and artisans are usually more skilled in dealing with metal and wood, respectively. Nevertheless, training and equipping local artisans to deal with such matters would be more feasible than attempting to train urban youth as rehabilitation professionals who would be willing to work in rural areas.

In most Asian and Pacific developing countries, people trained as engineers or technicians do not work in the field of rehabilitation. One reason is a simple lack of awareness that engineering and technical skills, especially in mechanical and chemical engineering, are needed and can be effectively applied in rehabilitation. With increasing awareness, more technical personnel may be expected to be involved in addressing rehabilitation issues.

Qualified local orthotic and prosthetic diploma holders in developing countries of the ESCAP region often do not get jobs, especially in cities, where the overall terms of employment could be comparable to those in developed countries. As a result, there is a tendency for this group to migrate to developed countries, where they earn more.

Strong policies are required for promoting a more equitable rural-urban distribution of services and personnel trained in assistive devices. These policies will require strong implementation and political determination.

In most Asian and Pacific developing countries, technicians are generally trained on the job, rather than formally. A disadvantage of this approach may be that workers are trained to perform only one aspect of the production of a device. For example, one worker will be trained only in assembly while another will be trained only for metalwork.

Training of local technicians in advanced technical skills helps ensure that NGO projects are sustainable in the long term. For example, most of the workforce in an NGO factory in Phnom Penh is Cambodian, but all the technical experts are expatriates. Local personnel, trained to develop the requisite technical expertise, would free that NGO to use its expertise elsewhere.

A. Recognition of technicians

The Agenda for Action for the Asian and Pacific Decade of Disabled Persons underlines the importance of recognizing rehabilitation technicians, to accord them higher status and encourage them to innovate. Professional technicians should be considered full members of rehabilitation service-delivery programmes, not as mere workers.

Employers of rehabilitation technicians often accord them low status and low wages. In Thailand, assistant technicians do not have job security. In many hospitals, a technician's workshop is not located near the area set aside for rehabilitation. Instead, it is often near the janitor's office and hardware maintenance rooms. This tends to result in poor communication between health professionals and technicians, leading to unrealistic expectations of what the technicians can accomplish. The consequences include poor follow-up. Furthermore, in societies where status and hierarchy are important parameters of functioning, it can inhibit technicians from expressing their views. This can prevent them from helping users in the way they consider most appropriate, and can also stifle the process of innovation.

As well as establishing a system of professional recognition, Governments could distribute newsletters, professional journals and bulletins written by and for technicians. This would not only demonstrate the value of their services, but also help establish a network and a sense of community among technicians to foster exchange of ideas. From there on, it may be possible to develop programmes or other means for technicians to achieve broader knowledge and thus enhance their work on assistive devices.

When new systems of training are introduced, some conflict may arise among technicians. Older technicians may be less well educated and less well trained, but they have higher status because of their seniority. This may make younger technicians afraid of introducing new methods. For this reason, it is important to upgrade the training of older technicians so that they may be technically on par with younger ones.

B. Levels of training

No one group can be responsible for all knowledge and training regarding assistive devices. At least four different groups need to be trained in Asian and Pacific developing countries:

- Expert technologists to fulfil multiple responsibilities, including researching, designing and developing new devices, serving as consultants and sources of the latest information on assistive devices, and training others: They could develop and conduct training courses for other personnel, such as mechanics, technicians, artisans and health workers. They could be a useful resource based at, but not confined to, rehabilitation centres in national or provincial/state capitals. Their training programme should follow international practice and guidelines to enable them to make appropriate use of new knowledge produced outside the region.

- Technicians capable of taking measurements, as well as producing and repairing devices: They are needed because of the great variety of devices required by people with different disabilities. In rural areas, steps may be taken to train community members as multipurpose technicians who can provide repair and maintenance services for many different types of devices.

- Village mechanics and artisans, including blacksmiths and carpenters, who should be trained in the repair and maintenance of devices: The making of many devices requires understanding and study of the human anatomy. These devices should only be produced by those with proper training. The development of training for village mechanics and artisans to support village health workers in rehabilitation is a new area of work to be pursued.

- Users, who should receive enough information to be able to make an informed selection of the devices they will be using: In addition, they require training in the safe and effective operation of the devices they select.

C. Training of technologists and technicians

There is a place for institutions which conduct formal training courses for technologists and technicians on assistive devices. Establishing such training courses may be beyond the reach of countries with limited resources, which need to make use of on-the-job training to ensure the production of as many devices as are needed.

Nevertheless, from a long-term regional perspective, training for workshops and production of devices is insufficient. A workforce with the skills for research and development is also needed. One way to develop these skills may be to introduce rehabilitation engineering into the curricula of engineering colleges.

A compact and detailed course over a period of two or three years would be useful to train highly qualified technologists in the area of orthotics and prosthetics. The potential role of such technologists is described above, in Section B on "Levels of Training. (See Box 16 for a suggested syllabus in such a course.)

Course duration for technicians, on the other hand, may range from two weeks to two months and include post-graduate training and technological updates. WHO has suggested the following guidelines for the formal training of technicians:

- Laboratory training should include general workshop procedures, woodwork, leather work, metal work, plaster work, thermoplastics, assembly of parts, and assembly of assistive devices;

- Academic training should include technology of materials, safety measures in workshop practice, reading of technical drawings, and use of workshop technology.

Proper fitting is essential to ensure that a prosthesis is comfortable. It is therefore important that prosthetic and orthotic technicians be well trained in fitting.

It is important that the training of technologists and technicians be perceived as education, not only as mere training. The tools and techniques in use may be changed regularly. Personnel should therefore be taught general skills and theory, not just the use of particular tools or techniques. They need, in effect, to learn how to learn.

Furthermore, education and training solely in the area of assistive devices are insufficient when not supplemented by education in other areas. Poorly educated technicians may, for example, be unable to understand manuals and other relevant documentation.

In considering the above guidelines, it is also instructive to bear in mind that disabled villagers created and run the Programme of Rehabilitation Organized by Disabled Youth of Western Mexico (PROJIMO). Projimo is an outstanding developing country example of an innovative rural rehabilitation programme. The projimo team makes assistive devices and provides rehabilitation services. The skills are acquired mainly through apprenticeship, mutual learning and from volunteer rehabilitation professionals and skilled technicians who devote their short visits to teaching skills. Since its inception in 1981, PROJIMO's assistive devices, designed with and for users, sometimes meet specific needs more effectively than those provided by large urban rehabilitation centres, and at much lower cost.24

D. National provisions for training

A few developing countries of the ESCAP region, including China and India, have specific legislative provisions for training rehabilitation professionals. According to 1996 projections,25 in the next five years, India will need around 1,000 orthotic and prosthetic engineers, 3,200 speech pathologists, audiologists and ear mould technicians, 500 rehabilitation engineers, 2,000 physical or occupational therapists and 50,000 CBR workers. There are several colleges and other institutions that train people in the relevant professional skills. Training is also provided by government agencies and NGOs. The Indian system is geared towards training people in rehabilitation technologies and methods available in India.

China has trained its personnel in orthotics and prosthetics using both internal and external resources. Chinese professionals are sent to Japan on a regular basis, while experts from Japan participate in annual seminars and training activities in China. Recently, under a bilateral technical programe with Germany, China set up the China Training Centre for Orthopaedic Technologists. The Centre will conduct four-year degree courses and enrol 20 new students each year.

In Pakistan, most technicians learn to make assistive devices through apprenticeship with master artisans. There are also formal training courses. The University of Peshawar offers a four-year course leading to a Bachelor's degree in prosthetics and orthotics. All polytechnic and vocational institutions offer courses in carpentry, machinist and metal work. Two universities offer physiotherapy courses.

The Sirindhorn National Medical Rehabilitation Centre in Thailand has a school for training 30 orthotic/prosthetic diploma holders every year. These students come from all over Thailand. In Chiang Mai, a degree course in orthotics and prosthetics may start within the next few years. A minimum of 12 years of education is generally required for entry to these schools.

Some other countries, including Indonesia and the Philippines, also have schemes to train prosthetic and orthotic professionals. Cambodia has established the National School of Prosthetics and Orthotics, which trains 12 new students per year as prosthetic and orthotic technicians. A school for training in the production and repair of orthopaedic devices is expected to start in Viet Nam in 1997, with the help of a German agency.

The training centres which are being opened have a strong emphasis on the use of thermoplastics, low weight and endoskeletal prosthesis, better comprehension of the alignment of devices, the principles of biomechanics and gait training.

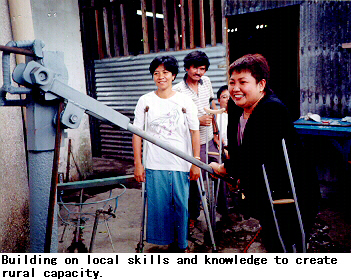

Building on local skills and knowledge to create production and distribution capacity in rural areas is a challenge to NGOs and government agencies concerneed with human resource development, rehabilitation and rural development.

In all these endeavours, it is important to bear in mind that people with disabilities should be given every assistance to participate in the training programmes. If necessary, pre-course education programmes may be organized, to assist prospective trainees with disabilities to attain the basic education level for course participation. Those programmes may include other components designed to encourage the development of self-esteem, interpersonal skills and the ability to make fullest use of a new learning environment. By shifting the focus to include emphasis on the training of people with diverse disabilities in the production, design, repair and maintenance of assistive devices, it may be possible to address in a significant way the need for skills in this field.

Box

Box 16: Curriculum for Prosthetic and Orthotic Technologists

The proposed duration of a formal course for prosthetic and orthotic technologists is 18 months and the ratio between laboratory practice and academic subjects 7:1. A model syllabus is suggested here. This syllabus is only a sample, and should be adapted to fit the needs and resources of the country or area in which a course is being established.

| Yearly Schedule of Three-Year Course | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Source: Excerpted from The Proposal Plan of Asia Prosthetic and Orthotic Center: Aiming for the Improvement of Prosthetic and Orthotic Services in Developing Asian Countries, prepared by the Japanese Association for Prosthetics and Orthotics (International Committee), 1993.

Go back to the Contents

ECONOMIC AND SOCIAL COMMISSION FOR ASIA AND THE PACIFIC

Production and distribution of assistive devices for people with disabilities: Part 1

- Chapter 8 -

Printed in Thailand

November 1997 1,000

United Nations Publication

Sales No. E.98.II.F.7

Copyright c United Nations 1997

ISBN: 92-1-119775-9

ST/ESCAP/1774