Nothing About Us Without Us

Developing Innovative Technologies

For , By and With Disabled Persons

Part Two

CREATIVE SOLUTIONS FOR WALKING

AND FOR LEG AND FOOT PROBLEMS

Introduction to Part Two

New Approaches to Meeting Common Problems

PART 2 looks at methods, aids, and equipment related to walking, and at ways to correct or cope with various problems in the legs and feet. The first several chapters in Part 2 (Chapters 11 to 14) look at leg braces (calipers). Chapters 18 and 19 concern artificial legs.

Use of Plastics. The introduction of plastic as a basic material for making leg braces and other orthopedic appliances has been a big step forward. For many children who have had to wear heavy, uncomfortable, metal braces, the chance to use light-weight, comfortable, snug-fitting plastic braces can be liberating.

|

Part 2 of this book looks at the use of plastic - from simple throw-away containers to modern oven-molded polypropyrene. |

BRACES FROM JUNK PLASTIC. Professionally made plastic braces are often so costly that many people who need them cannot afford them. Fortunately, in various countries and communities, people have found ways to make plastic braces and other appliances at low cost - using everything from plastic cups and buckets to PVC water pipe and plastic sewage pipe.

The chapters in Part 2 will give a range of examples of these innovative uses of plastic to create low-cost braces and artificial legs. Two chapters explore ways that empty plastic bottles or plastic pipes can be used as "foot-tubes" to help correct in-turned feet.

"MODERN" BRACES. In addition to innovations with old plastic containers, PROJIMO uses "modern" plastic brace-making technology, simplifying it for use in a village workshop. Sheets of polypropylene plastic are oven-heated and draped over plaster leg casts to create individually designed braces.

Raymundo, a paraplegic brace-maker at PROJIMO, drapes a hot sheet of polypropylene plastic over the mold of a boy's leg, and trims off the excess. Oliver Bock (with beard), a visiting orthotist (professional brace maker), helps and teaches Raymundo.

Artificial Limbs. People in India have made one of the biggest breakthroughs in appropriate, low-cost artificial limbs: the Jaipur foot. But, because this is well-known and produced in many countries, Chapter 19 looks more closely at the Mukti limb, a leg made from a section of plastic drain-pipe.

Skeleton for Teaching. To better understand how a leg or foot can best be braced, or to plan effective therapy, it helps to have some understanding of how the bones, muscles, tendons, and ligaments work together. To demystify the anatomy of the lower limb, Chapter 20 introduces the design and use of a simple plywood skeleton used for teaching.

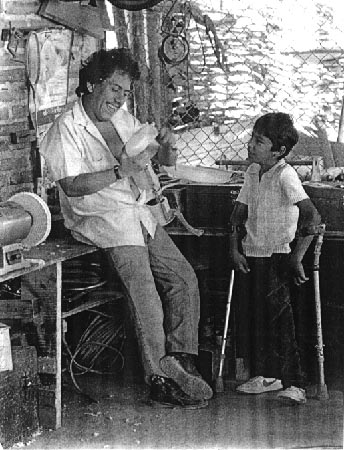

Participatory Problem Solving. As in the rest of this book, most of the chapters in Part 2 will focus on how the technologies described have been designed and adapted to meet the particular needs of a person with a disability.

Nothing About Us Without Us

Developing Innovative Technologies

For, By and With Disabled Persons

by David Werner

Published by

HealthWrights

Workgroup for People's Health and Rights

Post Office Box 1344

Palo Alto, CA 94302, USA