Disabled Village Children

A guide for community health workers,

rehabilitation workers, and families

PART 3

WORKING IN THE SHOP:

Rehabilitation Aids and Procedures

CHAPTER 64

Decisions about Special Seats and Wheelchairs

In this chapter we look at the things you will need to consider when buying or building a special seat or wheelchair, to best meet the needs of a child. Adaptations of seats and wheelchairs for special positioning needs are discussed in Chapter 65. Designs for building 6 basic wheelchairs are in Chapter 66.

Meeting the needs of the individual child, family, and community

Most children who need a wheelchair or special seat have severe weakness in parts of their bodies, or muscles that pull them into awkward or deforming positions. Seating should, as much as possible, keep these children in healthy and useful positions. It must provide support, but also allow them enough freedom to move, explore, and develop greater control of their bodies. For example:

![]()

|

1. A child who is 'floppy' and slow to develop ability to sit, |

2. may at first need a seat with straps and supports to hold her up.

|

3. As she develops better head control and then body control, the supports can be removed little by little,

|

4. until finally - if possible - she is able to sit anywhere, with little or no special supports. Now low back support is all she needs.

|

|

CAUTION: If a child needs to be supported as much as the one in the second picture, do not keep her strapped in her seat for long. She also needs periods of free movement and exercise to develop more independent head and body control. Keeping her strapped in for too long, or providing too much support after she has begun to gain more control, may actually slow down her progress. Seating needs to be changed and supports reduced as the child develops. Also, children who do not feel in their butts need frequent position changes and 'lifting' (see Page 198), and special cushions (see Page 200). |

Special seats and wheelchairs need to be adapted not only to the individual child, but also to the particular family, local customs, and community situation. For example:

|

A 'high chair' lets the child join the family that eats at a table. |

A 'low chair' lets the child fit in where the family eats at ground level.

|

|

Also, a 'high' wheelchair may be helpful where cooking and other activities are done high up. |

But a low 'wheelboard' or 'trolley' may be better where cooking and other activities are done at ground level. |

It is also important to consider the type of ground surface on which a wheelchair will be used.

Where land is flat and fairly smooth, and entrance into houses is level, a chair with a small wheel at the rear may work well and be less costly to make.

But where there are curbs, steps, rocks, or other obstacles, a chair with small wheels at the front works better.

On rough, sandy surfaces wide back tires and relatively large, wide front casters make moving about much easier.

|

Having the right wheelchair for the local situation frees the child to move about more easily in the community. |

Healthy, comfortable, and functional positions

Whether or not a chair has wheels, the position in which it allows a child to sit is very important. (See Chapter 65.)

For most children, the chair should help them to sit more or less like this:

|

|

|

|

CAUTION: The seat should be wide enough to allow some free movement and narrow enough to give needed support (see Measurements, Page 602). |

![]()

Common seating problems and possible solutions

Problem: Hips tilt back

In children with spastic cerebral palsy the hips often stiffen backward. This triggers spasms that straighten the legs and cause other muscle tightness with loss of control.

Also, children with weak hips or back, from spinal cord injury, spina bifida, or severe polio, often sit slumped with their hips tilted back and the back severely curved. This can lead to permanent deformity.

One of the most common causes of backward tilting hips is a chair like this one that is too big for the child.

Other causes of backward tilt and bad position are:

a chair back that tilts far back

and a cloth back that sags.

These let the child lean back and cause the hips to slip forward.

Also, footrests that are far forward so that knees do not bend enough can increase spasticity that tilts hips back.

A good position can often be gained through:

a fairly stiff, upright back at a right angle to the seat,

a chair that fits the child so that his hips reach the chair back,

the knees at right angles, and feet firmly supported.

Most children and especially a child who tends to fall forward in his seat, will sit better and more comfortably if the whole chair tilts back a little. But be sure to keep right angles at hips, knees, and ankles.

|

To tilt the chair back, the rear wheel mount can be moved higher up. You may also need to move the wheel mount back rather to keep the chair from falling backward with going uphill. Be sue the front caster barrel is still straight up or making turns will be harder. |

Keeping cost down and quality up

For many families, a wheelchair can be a great or even impossible expense. There are many ways to keep costs down. But be careful. Some low-cost choices may make the chair too clumsy, weak, or unsafe. Other low-cost choices may actually increase the chair's usefulness and life. For example, a very useful, long-lasting wheelchair can be made of wood-or from a cheap wooden chair. Even wheels made of wood (if made well) may work well and last a long time. But, making the hubs or bearings of wood usually leads to trouble. Standard wheelchair wheel bearings are very expensive. However, you can often get strong, high-quality, used metal bearings free or very cheap at electrical appliance repair shops or auto repair shops.

Factory-made or homemade wheelchairs?

Often you can save money by making your own wheelchair or by asking a local craftsperson to make one. Also, a homemade chair design can be more easily adapted to your child's particular needs.

On the next pages we give information that may help you decide about different wheelchairs and effective low-cost ways to make them.

You can make a fairly effective low-cost wheelchair by attaching bicycle wheels or wooden wheels to an ordinary wooden chair. Also, it is easier to attach special aids or supports to a wooden chair than to a metal chair. This design is adapted from AHRTAG's booklet, "Personal Transport for Disabled People" (see Page 604).

|

Any wheelchair is better than none-but sometimes not much better. Look for low-cost alternatives that make a chair better-not worse. |

REMEMBER: A wheelchair needs to satisfy the rider- not just the maker. Before (and after) buying or making a chair, think carefully about the different features that will help it best meet the needs of the particular child and family.

When buying or making a wheelchair (or any other aids), consider:

-

Cost. Keep cost low but quality high enough to meet the child's needs (see Page 592).

-

How long will the chair last? The longer the better, unless it is only for temporary use.

-

How easy and quick is it to make? The easier and quicker the better, as long as it meets your needs.

-

Availability of materials. Make use of local low-cost, good-quality resources (local wood, cheap metal, used bearings, bike parts, etc.).

-

What tools and skills are needed to make it? If welding equipment or skills are not locally available, a wooden chair may be a more practical choice.

-

How easy will it be to adjust or repair? Wood chairs that are bolted together are often the easiest to adjust or add special supports to.

-

Weight. The lighter the better, while making sure it is strong enough.

-

Strength. Heavier persons need stronger chairs and stronger axles. (A small child's chair may be supported by a bicycle axle attached on one side only. A bigger child needs the axle to be supported on both sides, or a stronger axle. See Page 598 and 615.)

-

Width and length. The narrower and shorter the better while meeting the child's needs (but not so short that it tips over easily).

-

How easily can it be moved- by the child sitting in it or by someone behind? How easily can it be tilted back to go over rough spots? Lifted up stairs? Transported? (Does it need to fold to take up less space?)

-

How well is it adapted to the particular child's wants and needs? Is it comfortable? Does it allow the child to sit in a healthy position?

-

Fit and growth factor. How well does it fit the child now? How long will it continue to fit her? Can it be adjusted to fit her as she grows?

-

How well is it adapted to living situations, the home, local customs, width of doorways, surface of floors and roads, curbs and other barriers?

-

Appearance. Is the chair attractive? Does the child take pride in it? Do other children want to ride it?

In considering choices for the design, building materials, and special features of a wheelchair, be sure to carefully consider the above questions.

Design choices for wheelchairs

|

FEATURE |

DESIGN DETAILS |

ADVANTAGES |

DISADVANTAGES |

|

WHEEL SIZE AND POSITION 2 big wheels with 1 or 2 small caster wheels

|

|

|

|

|

4 small wheels

|

Very simple temporary chairs can be made by putting 4 wheels on an ordinary wood chair.

|

|

|

|

3 big wheels

|

|

|

|

|

Some riders have 2 chairs: one like this for road travel, and a smaller one for home or work. |

|||

|

BUILDING MATERIAL FOR FRAME Steel tube

Whirlwind wheelchair See Page 622. |

AHRTAG design. see Page 604.

|

A strong, long-lasting, fairly light chair can be made better and cheaper than most commercial chairs. |

|

|

Wood

|

For wood design details, see Page 615 and 620and references on Page 604.

wood chair model design, see Page 615 |

plywood model design Page 620 |

(For tighter joints and more adaptability, use nuts and bolts instead of nails.) |

|

FEATURE |

DESIGN DETAILS |

ADVANTAGES |

DISADVANTAGES |

|

Re-bar (metal reinforcing rod used to strengthen cement)

|

Design can be the same as for metal tube chairs, but it is easier to adapt because the re-bar is easy to bend. |

|

|

|

PVC pipe (plastic water pipe)

|

|

|

Therefore it may be necessary to fiberglass the frame-which adds to cost, work, and weight. |

|

SEATS AND BACKS Soft canvas or leather stretched between supports

|

|

|

|

|

Firm (but padded) back and seat

|

|

|

|

|

Woven seat and back

|

|

|

|

|

FEATURE |

DESIGN DETAILS |

ADVANTAGES |

DISADVANTAGES |

|

TIRES Pump-up with air 'balloon' tires

|

Puncture-proof inner liners may be available. |

|

|

|

Solid tires (standard wheelchair wheels)

|

Buy from wheelchair supply center to fit diameter and width of rim. |

|

|

|

Rubber hose inside bicycle tire

|

|

|

|

|

Thin strip of old car tire

|

|

|

|

|

large machinery fan belt (discarded)

|

|

|

|

|

Piece of old bicycle or scooter tire

|

|

|

|

|

BIG WHEELS Standard factory-made wheelchair wheels

|

|

|

|

|

Bicycle wheels (rims and spokes)

|

|

|

|

|

Bicycle rims with wooden spokes

|

|

|

|

|

FEATURE |

DESIGN DETAILS |

ADVANTAGES |

DISADVANTAGES |

|

Wood wheels -big or small

|

|

|

|

|

CASTERS AND WHEELS

(Caster means that the wheel can swing in different directions for making turns.) Standard wheelchair caster wheels |

If possible, get (or make) casters with ball bearings. |

|

|

|

Casters from other (non-wheelchair) equipment (used or new)

|

|

|

|

|

Bent and welded steel caster forks

|

|

|

|

|

HUBS, BEARINGS, AND AXLES Standard wheelchair bearings

|

|

|

|

|

Bicycle bearings and axles

|

For mounting alternatives, see wheelchair designs Page 598 and 615. Also, see the AHRTAG Manual (see Page 604). |

|

|

|

FEATURE |

DESIGN DETAILS |

ADVANTAGES |

DISADVANTAGES |

|

Rear bicycle wheel axle and bearings

|

|

|

|

|

Used machinery bearings

|

|

|

|

|

Wood bearing

|

|

|

|

|

SUPPORT OF AXLES Axle supported on one side only

This is the standard mount for factory-built chairs. |

|

|

FOR SMALL CHILDREN ONLY |

|

Axle supported on both sides This can be done in several ways:

|

|

|

|

|

FEATURE |

DESIGN DETAILS |

ADVANTAGES |

DISADVANTAGES |

|

TO FOLD OR NOT TO FOLD A typical folding chair

|

|

Folding:

Non-folding:

|

Folding:

Non-folding:

|

|

ARMRESTS No armrests

|

Note: Many chairs are built so that armrests are part of the main structure and strength of the chair The armrests cannot be easily removed, even though this might benefit the child. Carefully consider the child's need for armrests before buying or making a chair |

|

|

|

Fixed armrests

|

|

|

|

|

Removable armrests

|

|

|

|

|

FEATURE |

DESIGN DETAILS |

ADVANTAGES |

DISADVANTAGES |

|

FOOTRESTS Positions In adult chairs, footrests often angle legs forward to leave room for casters.

For a small child, often footrests can position legs straight down. This is important in many cases (see Page 591).

A larger child may need to sit on cushions so that his feet are above the casters. |

|

A footrest like this,

may help feet like these.

|

To prevent or correct contractures, one or both legs may need to be kept as straight as they will go. |

|

Fixed position footrests The height of the rests should be carefully measured to fit the child who will use them. (For measurements, see Page 602.)

REMEMBER: Cushions or seating adaptations will change the height needed for the footrests. |

|

|

|

|

Removable or swing-away footrests wood chair swing-away footrest

|

There are many designs. Here we show one for the wood chair shown above and one designed for a metal chair. Other designs for sliding or swing-away footrests are on pages 616, and 622.

metal chair footrest See Page 622. |

|

|

|

Adjustable footrests

Also serves as storage shelf.

|

There are many designs. Here is one of the simplest, for a plywood chair.

|

|

|

|

No footrests

|

|

|

|

|

FEATURE |

DESIGN DETAILS |

ADVANTAGES |

DISADVANTAGES |

|

PARKING BRAKES lever brakes

|

There are many brake designs. This one is from AHRTAG. Two others are on Page 623.

|

|

|

|

Parking block

|

Brakes on wheelchairs are for keeping the chair from rolling when getting in or out, or stopped on a hill.

|

|

|

|

HANDRIMS FOR PUSHING Designs taken from ARHTAG. See Page 604.

|

|

|

|

|

Handrim grip improvers Cut a piece of rubber hose lengthwise and tape it onto rim.

|

|

|

|

Fitting the chair to the child: measurements

These measurements are for wheelchairs and for special seating without wheels.

SEAT WIDTH

Note: Some specialists recommend wider seats. But the child gets a better arm position for pushing the wheels if only 1 cm. is added on either side. However, you may want to leave a little more room to allow for the child's growth.

SEAT DEPTH

Note: You may want to add 2 cm. or 3cm. to allow for growth - and use a backboard or firm cushion to fill in the extra space.

|

CAUTION: When measuring, be sure to allow for cushions or backboards that will be added. |

SEAT HEIGHT

|

CAUTION: Be sure to include cushion when measuring height for chair seat. |

Note: Raising the seat of a small child higher lets his feet rest above the casters and therefore directly below the knees. The higher seat also helps for eating at the table with the family. Sideways transfers are also easier. Sometimes seats are placed even higher than shown, but this makes pushing wheels with hands more difficult.

ARMREST HEIGHT

MEASURE FROM BOTTOM OF BUTT TO BEND OF ELBOW.

Before measuring, be sure child is sitting as straight as possible.

Put armrest height a little higher than his elbow so that the elbow will be positioned away from the body.

Note: This measurement is standard, but some children need arm support at a higher level. Experiment.

BACK HEIGHT

MEASURE FROM BOTTOM OF BUTT TO ARMPIT.

Note: This measurement is standard, but some children need a higher back, and sometimes head support. Others prefer a back that supports only the hips.

IMPORTANT: Also check how much hips and knees bend, as this may affect position of footrests and casters.

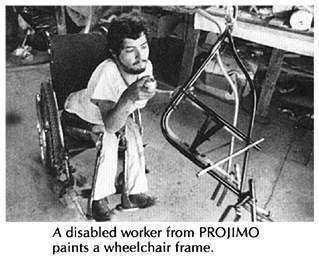

Wheelchair production as a small 'village-industry'

In several countries small groups of disabled persons have started to produce low-cost, good-quality wheelchairs adapted to local needs. Usually this is in places where standard factory-made wheelchairs are very high-priced and are not suited for use on rough or sandy ground.

Some of these 'little factories' try to be self-sufficient. A few have even succeeded in making a modest profit, while keeping prices low.

Sometimes, a small-scale wheelchair making and repair shop is set up as part of a community rehabilitation program. Self-sufficiency (selling the chairs for a little more than it costs to make them) is often a goal. But because families with the greatest need are often least able to pay, the chairs must often be sold below cost.

WHAT KIND OF WHEELCHAIRS TO MAKE

This depends on many factors: cost, skills or training available, tools and equipment needed, amount of money available to start, building materials available, the possible market, the local economy, and needs of the wheelchair user and family.

For example, folding tube-metal chairs are relatively expensive to make and require more skill, training, and equipment. However, they often work smoother, last longer, and are easier to transport than are many other models. These high-quality, good-looking chairs - painted or even chrome plated - may sell the best, even if expensive, and may compete with factory-made chairs (see Page 622).

If the wheelchair users will be mostly children and poor families, low-cost wooden chairs may be more appropriate. These can be easily built to size and adapted to the needs of the individual child. The chair may not last as long. But the child is growing and her needs may change. Simple wood chairs also require fewer skills to build - mainly carpentry. They are easier for the family to build, repair, or add changes to at home.

Ideally, a village shop would make a variety of chairs out of different materials and at different prices. Chairs of all models, sizes, and adaptations should be kept on hand to give the child and family a chance to know and try different possibilities. Be sure to make child-sized chairs. And make chair inserts so that adult-sized chairs can be adapted for children.

Look for every opportunity to keep costs low. Providing repair services for used and broken chairs are good ways to keep children on wheels. Also use as much 'waste', and used and free materials as you can: old bicycle wheels, old machinery bearings, scrap metal, and bolts from junk yards. For basic building materials, check prices of different sellers. Once you are sure of what you need, try to buy large amounts at lower cost. If you explain to the sellers the purpose of your purchase, they may lower prices or give you useful scraps.

Designs for 6 different wheelchairs are in Chapter 66.

How-to-do-it Reference Materials for Wheelchairs, Wheelboards, and Other Seating

It is impossible, in a book such as this, to give detailed building plans for more than a few wheelchairs, scooters, wheelboards (trolleys), and special seats. The following reference materials have more detailed plans. You can send for them at the addresses shown. Some may also be available from TALC, P.O. Box 49, St. Albans, Herts, AL1 4AX, England. With each reference we give one or more drawings of key designs and a few comments about their usefulness and cost.

Personal Transport for Disabled People-Design and Manufacture

AHRTAG Farringdon Point 29-35 Farringdon Road London EC1 M 3JB ENGLAND

Also available through TALC

- many good designs and plans for low-cost aids

- does not compare strengths and weaknesses or describe limitations of different designs

- no design for wheelchairs with casters in front (which are needed for many areas)

Independence through Mobility: A Guide to the Manufacture of the ATI-Hotchkiss Wheelchair

by Ralf Hotchkiss

c/o Wheeled Mobility Center Dept. of Engineering SFSU San Francisco, CA 94132, USA

- design for the 'whirlwind', a high-quality middle-cost steel tube wheelchair that can be built by disabled craftspersons as a village industry

- short training usually needed to build it effectively; welding skills and simple math required

- cost of materials about US $100

Local Village-made Wheelchairs and Trolleys

by Don Caston

Available upon request.

DON CASTON 202 Cheesman Terrace London W 14 9XD ENGLAND

- simple, very low-cost aids, made mostly out of wood, using bicycle or wood wheels

- all models are based on one 3-wheel trolley design

- Instead of a standard caster, the front slides on its axle and is pushed back to center by a choice of simple methods. (This method is cheap and clever, but unstable and does not turn as well as designs with casters.)

Asia-Pacific Disability Aids and Appliances Handbook, Part 1: Mobility Aids, 1982

ICTA Box 510 S-162-15 Vallingby, SWEDEN

- brief descriptions and non-technical drawings and addresses for information on many aids.

An Accent Guide to Wheelchairs and Accessories

ACCENT P.O. Box 700 Bloomington, IL 61702 USA

- information about different aids, features, and accessories of factory-made chairs

- basic information on cleaning and repairing

- design and building information limited to a few accessories

UPKARAN -A Manual of Aids for the Multiply Handicapped

The Spastics Society of India Upper Colaba Road Near Afghan Church Bombay 400 005 India

- an excellent resource

- many simple, practical designs for seating, wheelchairs, crawlers, standers, walkers, therapy aids, and toys

How to Make Basic Hospital Equipment

by Roger England and Will Eaves

Intermediate Technology Publications 103-105 Southampton Row London WC1B 4HH ENGLAND

Also available through TALC and AHRTAG

- simple, attractive designs using tube steel

- welding skill required; fairly costly to make no designs for casters-in-front chairs

Poliomyelitis-A Guide for Developing Countries by R.L. Huckstep

Churchill Livingstone 5 S Fontenac Road Naperville, IL 60563 USA

- detailed designs for 3 models of wheelchairs commonly used in Africa

- only casters-at-rear designs (which often may not be the most appropriate design)

Positioning the Client with Central Nervous System Deficits: The Wheelchair and Other Adapted Equipment

by Adrienne Falk Bergen and Cheryl Colangelo

Valhalla Rehabilitation Publications, Ltd. P.O. Box 195 Valhalla, NY 10595 USA

- excellent detailed discussion of specific needs of children with cerebral palsy

- many well-illustrated examples

- written for developed countries but many aids and designs are simple and can be made anywhere at low cost

'Build Yourself' Plastic Wheelchair

Directions for assembly available from:

Spinal Research Unit Royal North Shore Hospital of Sydney St. Leonards, NSW 2065 Australia

- relatively expensive (materials about US $ 100)

- plastic frame made of 9 m. of 15 mm. PVC pressure pipe; plastic set of 8 mm. soft PVC tubing; 2 rear 24 inch bicycle wheels; 2 front casters (15 mm.)

- relatively expensive (materials about US $100)

- Plastic will sag with continued use.

- uses standard bicycle axles- which will bend with the weight of an adult or large child

- relatively lightweight

- does not fold

- design plan complicated and difficult to follow

Measuring the Patient

Everest and Jennings, Inc. Available through Everest and Jennings wheelchair dealers or:

Everest and Jennings 4203 Earth City Expressway Earth City, MO 63045 USA

- good information on measurements for standard chairs

- illustrated discussion of problems with chairs that do not meet a person's specific needs

SEAT HEIGHT

Functional Aids for the Multiply Handicapped

by Isabel Robinault

Harper and Collins Sales 10 East 53rd Street NYC, NY 10022 USA

- mostly factory-built examples but some are simple and well-illustrated enough to serve as design guides

- many good wood special seats

- also support frames, standers, walkers, toys, and eating aids

Disabled Village Children

A guide for community health workers,

rehabilitation workers, and families

by David Werner

Published by

The Hesperian Foundation

P.O. Box 11577

Berkeley, CA 94712-2577